Farm-to-Closet

Notes from four years as Christy Dawn’s director of regenerative practices

Almanacs are resources to understand how natural cycles interact with specific topics. Each month, The Mindful Designer’s Almanac offers musings about natural fibers harvested that month or season. In December, cotton farmers in India have started their harvest.

In December 2018, I was working in Oakland as the cotton program associate at the Responsible Sourcing Network, a non-profit focused on reducing forced labor in cotton supply chains. One morning, I sat in my boss’s office listening to a voicemail from the CEO of Christy Dawn, Aras Baskauskas. He wanted to grow cotton for their dresses in a way that didn’t hurt the earth and he wanted to see if we could help.

I was a few months out of college and trying to get clarity on what I would do with my life. By that morning in December, I had a clear idea. I had recently written down that within five years, I wanted to be the sustainability manager at one of four small clothing brands, including Christy Dawn. So to be getting this call a few weeks later from the CEO looking for sustainability-related help felt surreal.

The synchronicities didn’t stop there. I called Aras back, said I was interested in helping, and scheduled a time to meet in person. I went to the Christy Dawn office in January, and he explained that they were looking for about 1,000 yards of lightweight woven cotton, ideally block-printed with natural dyes. Most importantly, he wanted to know the farmers growing the cotton and the farm to use regenerative practices. The timing was perfect because Responsible Sourcing Network had lost some funding and only had the budget to keep me on half-time. I spent the rest of my time searching for a cotton farm that fit Christy Dawn’s bill.

I quickly learned that no farm existed that would be willing to make such a small amount of fabric, follow those practices, and work directly with brands. One afternoon in January, I drove up to Marin to meet with Rebecca Burgess, the founder of Fibershed, a non-profit that focuses on localized supply chains for clothing. She said she knew of a few projects in California that were many years out from producing fabric. On my way out, she said she had received an email earlier that day from a man in India who produced sustainable textiles and she would forward me his information.

His name was Nishanth Chopra. His company, Oshadi Collective, had been producing artisanal textiles in and around his hometown, Erode, Tamil Nadu, for a few years. He saw the positive impact of producing more thoughtfully and sustainably on his community and wanted to go deeper. He asked around and found a family willing to grow cotton on the four acres of land they leased. He just needed a brand to help finance it and to commit to using the cotton.

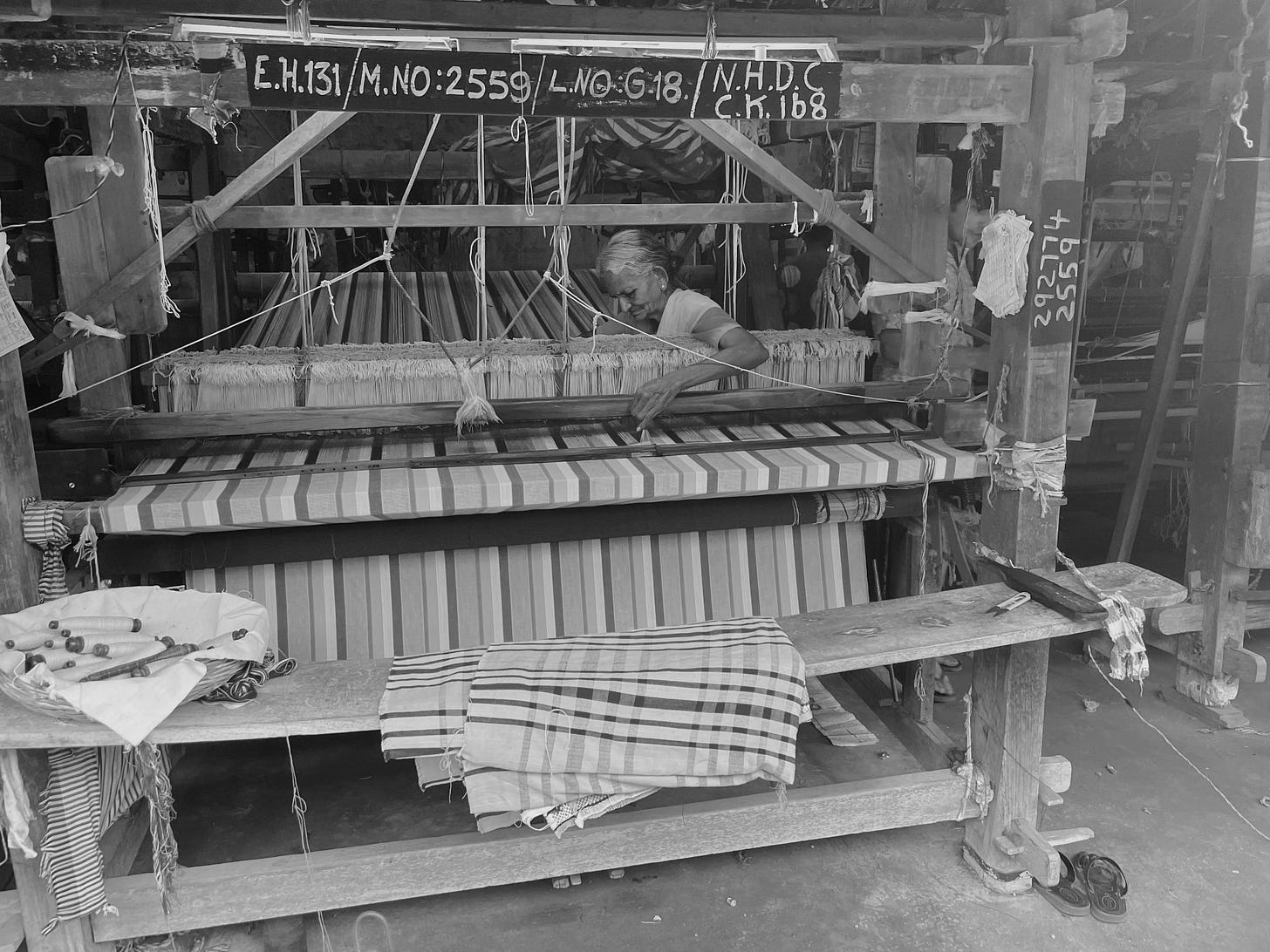

A little less than a year after Aras and I got on our first call with Nishanth, the two of us flew across the world to visit Nishanth and Oshadi Collective in person. We visited the local natural dye guru, went to hand-weaving studios, and met with the tailors working at the Oshadi office. Most of our time was dedicated to the farm— we spent every afternoon sitting and drinking tea with, or shadowing, the farmers, orienting ourselves to the farms’ processes, and discussing problems the farm faced and how to avoid them in the future. Although there were way more weeds than we would have liked, which is expected during the first year of transitioning from chemical-dependent practices back to traditional ones, the cotton plants were strong. The farm plan we had been developing over almost daily phone calls the six months before was working.

Nishanth found a variety of long-staple cotton native to the farm’s region. I found a guide to organic cotton farming in Southern India that had a list of suitable cover crops for us to try. He met with farmers around his community who still used traditional techniques, such as spraying pest-ridden plants with tea containing cow urine, tobacco, ginger, garlic, and green chillis. Oshadi’s farm manager, Vaishali, shared research she found on low-budget farming– a technique that uses only resources grown in and around the farm to aid growing with far fewer external inputs. We kept adding our combined research to formulate our version of a regenerative farming plan for Southern India.

By the time Aras and I arrived in India, our farm plan included how to reduce the weeds and prevent this kind of weed explosion from happening in future seasons. Aras and I knew everything else that was happening on the farm, not just because of my frequent calls with Nishanth, but also because I was looking over every farm expense and Christy Dawn was paying the bill for every single cost of growing cotton regeneratively, including a living wage for the farmers.

Without any experience working for a for-profit company, I didn’t realize just how radical it was for Christy Dawn to pay this bill. It made sense to me: all the cotton from the farm was going to Christy Dawn dresses that it would profit from, so it seemed fair to pay for growing the cotton. What I quickly learned is that most brands don’t pay for the cotton in their clothing until just before they sell the clothing made with it, or with net 30, 60, or 90 day terms, after it sells. In most cases due to commodification, slavery, and subsidies, brands pay way below the actual price of growing the cotton. But Christy Dawn paid for everything down to the sugar in the chai the farmers drank on break. In the case of the first season of farming, this payment plan meant we paid for the cotton in our dresses a year and a half before we profited from it.

During that year and a half, we had to figure out how to not only regeneratively grow the cotton but how to then turn that cotton into Christy Dawn dresses. Southern India is the only place in the world where we could successfully do this. Starting with the seed — Surabhi cotton is a non-GMO cotton that thrives in Tamil Nadu’s soils. Most importantly for Christy Dawn dresses, it is a long-staple cotton that can turn into a very fine yarn and a fine, lightweight fabric. Once the farmers harvested and sorted this fine cotton, we had to figure out how to gin, spin, and weave it segregated from other farms’ cotton. India is one of the only cotton-growing countries that still relies on small gins in every cotton-growing town. The cotton from our 4 acres was enough for one day of ginning, so Nishanth convinced a local gin to shut down normal operations for a day to gin our cotton. Same story at a small, local spinning mill.

Christy designed a handful of different fabrics for our first Farm-to-Closet collection. Some of the yarn went to hand-weavers, some went to the natural dyer, some was machine woven and then sent to Northern India for block printing, and some was digitally printed with a low-impact printer. The fabric we made the highest volume of was mid-weight cotton voile. Christy was skeptical at first, the raw fabric was stiffer, not as soft and flowy as she would have liked. Then we received yardage of it naturally dye block printed. I am not sure if it’s because the community who printed it practices Ayurvedic traditions to preserve the benefits of plant dyes on the skin or because the traditional washing process includes hitting the fabric against the side of a water vat over and over again. Regardless the resulting fabric had the perfect soft hand and drape for Christy Dawn dresses and was exactly what Aras asked me to find two years earlier.

A block printer washing the mid-weight voile printed with indigo.

It’s been exactly five years since the first cotton harvest started in December 2019. A majority of the fabric in Christy Dawn dresses is that same soft, regeneratively-grown mid-weight voile. Since this first farm, Christy Dawn has invested in and used the cotton from over 300 acres of regenerative cotton farmland with Oshadi Collective and produced eighteen collections of Farm-to-Closet dresses. Although I left my full-time role at Christy Dawn two years ago, I’m so grateful for all the synchronicities that allowed me to work on this project, in part because I got to put into practice how I think clothing should be made.

When I worked at Responsible Sourcing Network, I reread one of my favorite essays, Aldo Leopold’s Land Ethic, to guide me as I created my own ideas around how to sustainably and ethically produce clothing. He argues that you have to experience nature to have an ethical relationship with it because, “We can be ethical only in relation to something we can see, feel, understand, love, or otherwise have faith in.”

In the case of clothing, Leopold's logic means brands cannot be ethical (or sustainable or regenerative or whatever buzzword) with a partner they do not know. Most brands use standards and certifications to “get to know” their suppliers and practices. Although standards and certifications prohibit inputs and practices that are universally harmful, it’s hard to believe that this check-box approach captures the nuanced environmental, cultural, and financial considerations needed to make clothing ethically in different geographies and with unique communities. Standards and certifications are a great way to reduce the bad, but reducing the bad is not enough. Brands need to start working on increasing the good to offset their peers and their own bad practices. This can only happen once brands forge direct relationships with the people and soil that make their clothing.

I think about this process as turning the negative feedback loop that the clothing industry relies on into a positive feedback loop. A vast majority of brands and clothing supply chains rely on top-down approaches where in order for someone (usually brands) to win (make a lot of money), someone else (usually everyone else, including the customers) has to lose (get extracted or exploited). During my time building and tracing Christy Dawn’s supply chains, I was constantly looking for ways for both the brand and our partners to benefit. For example, we focused on improving biodiversity on the farm, but the other crops we introduced benefited the cotton. So, biodiversity increased, and our yield and quality of cotton improved. Although we took more steps in the right direction than other brands, we did not achieve a perfect positive feedback loop. It's a continuous process, Christy Dawn will always have the opportunity to improve their positive impact.

My time at Christy Dawn did show me that it doesn’t have to be a zero-sum game, a brand can be profitable and benefit the people and planet producing its clothing. It will just be less profitable. It’s expensive to research and understand complex fiber and clothing supply chains. Once a brand begins to understand its supply chain, it’s expensive to address any issues that arise. A brand will make less money if it pays everyone growing and making clothing a fair wage, uses regenerative farming methods, relies on small-scale manufacturing, and supports traditional crafts than brands that choose conventional, extractive routes. Increased timelines, limitations on what materials designers can use, and limited raw material quantities also can affect profitability. Brands often point to lost profits to justify not doing proper due diligence in their supply chains. It’s a “you can’t help someone else until you help yourself” argument: an ethical supply chain might put the company out of business. But it shouldn’t. The brand just has to be willing to adjust, get creative, and be okay with losing some excess, including excess profits.

To me, making clothing this way is a no-brainer because it's the right thing to do. To return to Leopold’s Land Ethic: “A thing is right when it tends to preserve the integrity, stability, and beauty of the biotic community. It is wrong when it tends otherwise.” Supporting basic human rights, contributing to a clean and healthy environment, supporting artisanal crafts, and most importantly preserving the biotic community and cultural traditions for future generations is right. Excessively producing clothing and profiting off of extraction and exploitation is wrong.

There's nothing like someone passionate about their field sharing their knowledge and insight in a manner that's accessible to people with little experience in the field. I appreciate how you detailed the process of ensuring that the cotton was sustainably produced.

An inspiring essay to read at the beginning of 2025 — thank you!